Functional Safety Plan and Safety Schedule

Thanks to many years of experience at NTC Systems, we can plan safety projects in the field of electrical and electronic systems precisely. We initiate the functional safety life cycle according to the V-model for your project and define the safety objectives and requirement levels ASIL-A to ASIL-D or SIL-1 to SIL-4.

To implement the functional safety plan, we assign roles and responsibilities. Our experienced functional safety managers (FSM) create the safety schedule. Of course, we also coordinate and monitor this.

Agreement on the services interfaces

We prepare the conclusion of a Development Interface Agreement (DIA) between you and your suppliers, as required by standards and norms like the ISO 26262, for example.

To this end, we define the responsibilities between you as the manufacturer and your suppliers by precisely classifying and documenting the safety activities in the concept phase, the development phase and the production phase.

Functional Safety Consulting

We analyze your safety processes and develop recommendations on how you can effectively and successfully organize functional safety in your company.

Functional Safety Verification

We provide you with a complete substantive argument for the correctness of the functional safety concept and demonstrate compliance with all safety requirements defined in the relevant standards.

Functional Safety – Pre-Assessment

In preparation for the release of your product, we prove that the safety requirements for your project / system, e.g. according to ISO 26262, are completely fulfilled. For the evidence, we check the work results of the safety activities during the entire development process.

Our safety experts list all the work results of the safety activities for the safety proof: Reviews, FMEA, design documentation, safety concept, etc..

For each individual work result, we indicate how it ensures product safety.

Normen | e.g. ISO 26262 (ASIL-A to ASIL-D) und IEC 61508 (SIL-1 to SIL-4)

Functional Safety (Pre-)Audit

Our experts check the implementation of all processes that are necessary in the area of functional safety in your company. We then create audit reports and action reports.

Hand-in-hand with safety experts from NTC Systems

If you wish, our safety experts will also take a very responsible approach to your safety project!

Reference projects for functional safety management

Lighting system on autonomous cab | System development according to ASIL B

The FuSi experts at NTC Systems took on this work for the customer and supported him during development:

- In a self-driving cab, the functions of the exterior lighting system must be protected against failure and unwanted activation:

- Ensuring the visibility of the vehicle and its warning signals

- Illumination for optical sensors

- No glare or irritation of surrounding traffic

- Customer needs guidance and leadership in the area of functional safety

- Organization and planning of safety activities as well as communication with the car manufacturer

- Advising the customer on the procedure for creating the work products required by the standard

- Definition of a software development process

- Moderation of a Software FMEA

Picture: System development according to ASIL B

Development of a switch sensor for railway tracks – Safety Management in accordance with EN 50126

With its Safety Management, NTC Systems demonstrated to both external experts and railway inspectors that the switch sensor system meets the highest safety requirements.

NTC Systems’ contributions to this project

- Comprehensive safety analyses: NTC Systems carried out detailed safety analyses to identify potential risks and develop appropriate measures to minimize them.

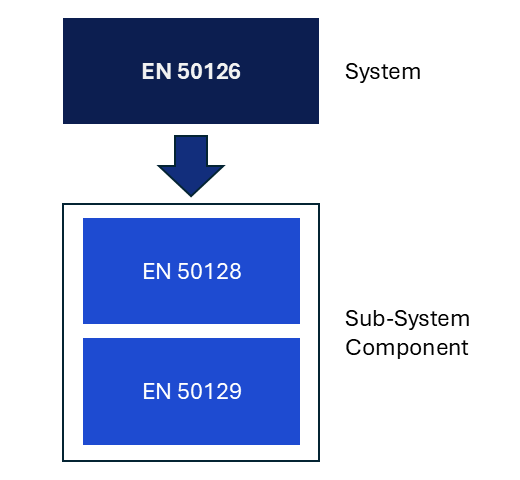

- Safety management plan: NTC Systems created a customized safety management plan that covers all relevant aspects of EN 50126 and EN 50128/EN 50129 and ensures that the development project complies with the highest safety standards SIL 4 specified here.

- Safety proof: NTC Systems created the comprehensive safety proof, which documents and verifies compliance with safety requirements.

What is EN 50126?

EN 50126 is a European standard developed specifically for the railway industry to ensure the safety of systems and components. It defines requirements for safety management and safety certification of systems and provides a clear framework for the development and implementation of safe systems.

What is SIL 4?

SIL 4 (Safety Integrity Level 4) is the highest safety integrity level according to the EN 50126 standard. In conjunction with EN 50128 and EN 50129, it ensures that systems and components have an extremely low risk of dangerous failures.

NTC also developed the hardware and software for the switch sensor system

For more details on these development services, see here >> E/E system development at NTC Systems

Picture: Safety Management according to EN 50126, EN 50128, and EN 50129

Reference Projects for Functional Safety – Management

- Automotive

- Railroad Technology

- Mechanical Engineering

- Medical Technology

- Automation and process Industry

Feel free to ask us for examples for your industry!